ATP architects engineers

Hilti, Thüringen, A

Production Building

Client: Hilti AG

Total Built Area: 18,600 m2

Total Built Volume: 182,000 m3

Construction Start: 2008

Completion: 2009

Awards:

European Architecture Prize 2009 Energy+Architecture – honourable mention.

Energy Globe Award Vorarlberg 2009 - honourable mention.

ÖGNI Certification in Silver, 2010.

Konstruktiv - (Liechtenstein Prize for Sustainable Building and Refurbishment in the Alps) 2011, honourable mention.

A competition with a preliminary evaluation procedure led to the selection of ATP’s entry combining a design for a new production building and a long-term plan for the development of the site.

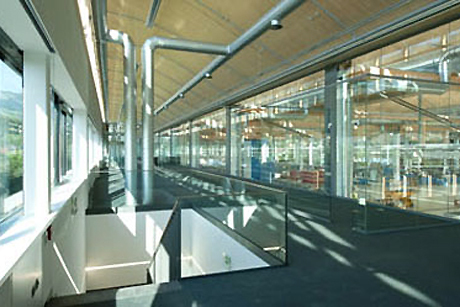

The new building combines production and logistics areas with a fully automated pallet and container store and peripherally organised support and office areas. While the 30m high high-shelving store is optically separated from the surrounding woodland by being realised as a black, vertically oriented cube the production areas are treated as a scaly metal monolith with shed roofs. The production building can be compared with a sort of metal moulding formed via a subtractive sculpting process. Together with the client a “Sustainability Brief” was drawn up. Energy efficiency was achieved by the innovative combination of building management technology, energy efficient hydraulic switching and creative solutions in the use of geothermal energy, ground water and extract air.

Fotos: ATP architects engineers/Thomas Jantscher

Client: Hilti AG

Total Built Area: 18,600 m2

Total Built Volume: 182,000 m3

Construction Start: 2008

Completion: 2009

Awards:

European Architecture Prize 2009 Energy+Architecture – honourable mention.

Energy Globe Award Vorarlberg 2009 - honourable mention.

ÖGNI Certification in Silver, 2010.

Konstruktiv - (Liechtenstein Prize for Sustainable Building and Refurbishment in the Alps) 2011, honourable mention.

A competition with a preliminary evaluation procedure led to the selection of ATP’s entry combining a design for a new production building and a long-term plan for the development of the site.

The new building combines production and logistics areas with a fully automated pallet and container store and peripherally organised support and office areas. While the 30m high high-shelving store is optically separated from the surrounding woodland by being realised as a black, vertically oriented cube the production areas are treated as a scaly metal monolith with shed roofs. The production building can be compared with a sort of metal moulding formed via a subtractive sculpting process. Together with the client a “Sustainability Brief” was drawn up. Energy efficiency was achieved by the innovative combination of building management technology, energy efficient hydraulic switching and creative solutions in the use of geothermal energy, ground water and extract air.

Fotos: ATP architects engineers/Thomas Jantscher